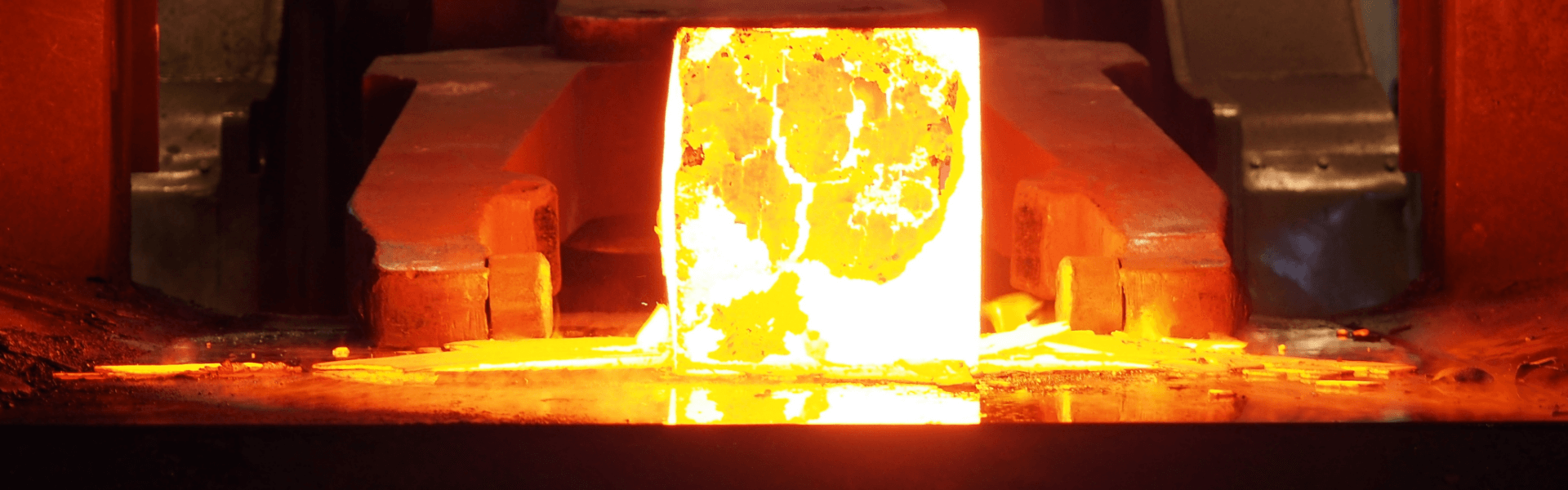

Forging on the steam hammer

This is awesomeBlacksmithing is one of the oldest crafts in the history of mankind. And even if we haven’t been working with hand hammers and anvils for a long time, the principle is still the same. Using steam hammers and hydraulic presses, combined with our many years of experience, we produce forgings that perfectly meet your specific requirements.

Then and now

We forge smaller pieces weighing between 50 kg and 2,500 kg on our modern steam hammers with a bear weight of between 300 kg and 6,000 kg and a hydraulic upsetting press.

Our forgings are moved under the hammer using electro-hydraulic manipulators.

Hammer forging enables us to produce the special quality of forming, especially with high-quality grades.

Open-die forging allows a free choice of shape and size of the manufactured forgings in individual and series production.

At a glance

- Nine steam hammers for forgings from 50-2,500 kg

- Single part and series production

- Suitable units for every shape and size of forged part